The short video below gives an idea of the process.

All this is known, but the question that is asked by many is whether there is any legal basis for carrying HAZOP? Well, the answer is Yes and No. If you are looking for some Bill passed in Congress or some Act of Parliament in some country that says you must do a HAZOP, then no. There is to the best of my knowledge, no such law. BUT many of the legal acts in various countries and other rules and regulations have some references. For example in the US, following OSHA guidelines is mandatory by law and their 14 elements of Process Safety Management (PSM) do include Risk Assessment of the process, where HAZOP is specifically mentioned.

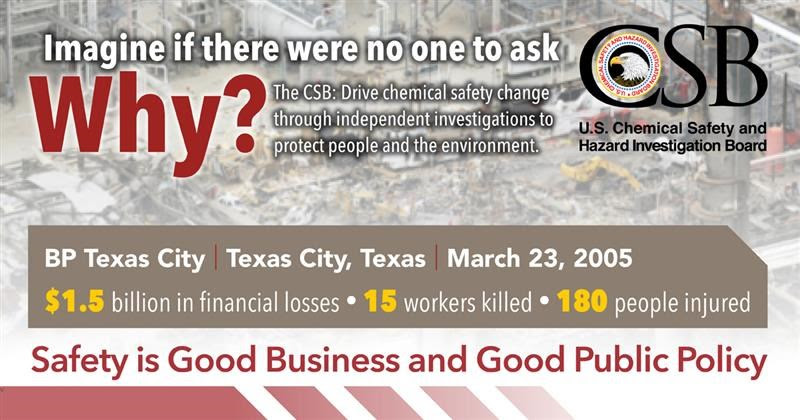

So while there is no direct law that says that you must do it, there are many indirect legal references that say that you must do it. Finally, all that matters is that if ever there is an accident AND the matter goes to court, the judge will be mighty annoyed if he/she discovers that you were not carrying out Risk Assessments such as HAZOP, especially when everyone else is doing it and it is given in OSHA guidelines and the fact that it costs much much less, than the cost of the plant (or the cost of the accident, which will be anyway more than the cost of the plant).

So now take your pick , whether to do it or not.

ss and ultimately a company’s bottom line.

ss and ultimately a company’s bottom line.