Do watch it to get new insight on the topic. As usual if you need more information on this then the best thing to to visit the HAZOP Training page and get trained and certified!

Wednesday, December 6, 2017

HAZOP Training Video

Here's an excellent video to everybody who wants to learn about Hazard and Operability Study (HAZOP) technique, in one easy video that takes baout 5 minutes to watch.

The video is in a very interesting format. It tells the concept in the form of a story of a greenfield chemicals manufacturing project. A young project engineer, wishes to know more about why they need to do a hazop study for it. Her boss, who is the project manager, explains in a very easy way of why and how it is done.

Do watch it to get new insight on the topic. As usual if you need more information on this then the best thing to to visit the HAZOP Training page and get trained and certified!

Do watch it to get new insight on the topic. As usual if you need more information on this then the best thing to to visit the HAZOP Training page and get trained and certified!

Tuesday, April 25, 2017

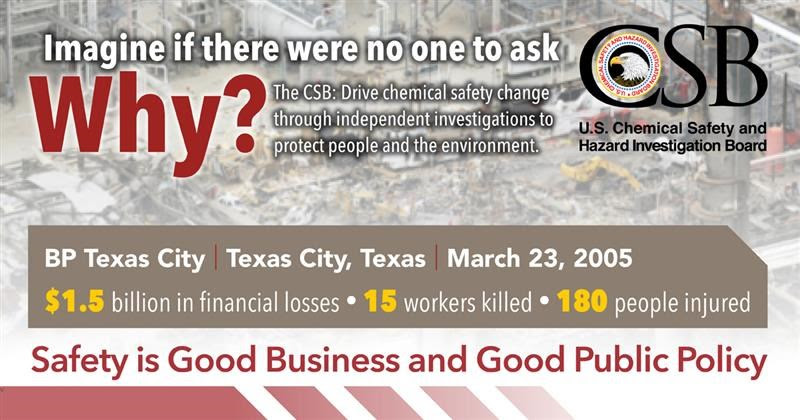

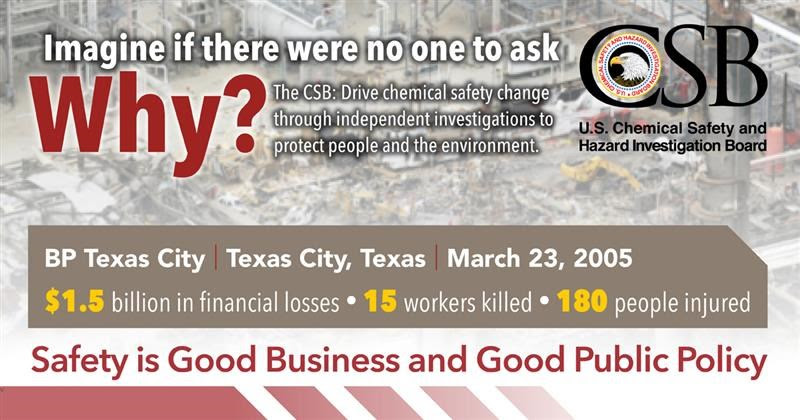

US Chemical Board publishes Business Case for Safety

April 14, 2017, Washington, D.C. - Today the CSB released a “Business Case for Safety” that summarizes four major accident investigations. The six page documents details how safety is good for busine ss and ultimately a company’s bottom line.

ss and ultimately a company’s bottom line.

Included in the business case are the costs associated with the 2005 explosion and fire at BP Texas City, the 2010 explosion and fire aboard the Macondo/Deepwater Horizon oil rig, the 2012 explosion and fire at the Chevron Refinery and the 2013 fire and massive explosion at West Fertilizer. Each of the four CSB accident investigation details both human and financial tolls which these incidents had on the company and the surrounding communities.

The CSB’s “Business Case for Safety” emphasizes that based on its more than 130 incidents it is clear that hundreds of billions of dollars have been spent as a result of chemical disasters in the United States. To ensure the safety of all Americans it is critical that chemical safety lesson are learned and shared among

diverse stakeholders and across industries to prevent accidents.

Chairperson Sutherland said, “If the CSB’s many safety lessons prevented at least one catastrophic incident, the money saved by preventing damage to the facility and surrounding community, avoiding legal settlements, and saving human lives far exceeds the agency’s $11 million annual budget.”

The CSB concludes that strong safety programs are critical for the economic success of the chemical and petrochemical industries. The CSB’s continued collaboration with industry, regulators, standards setting bodies and other professional organizations proves that the CSB has a vital role in driving critical chemical safety change in the United States.

ss and ultimately a company’s bottom line.

ss and ultimately a company’s bottom line.Included in the business case are the costs associated with the 2005 explosion and fire at BP Texas City, the 2010 explosion and fire aboard the Macondo/Deepwater Horizon oil rig, the 2012 explosion and fire at the Chevron Refinery and the 2013 fire and massive explosion at West Fertilizer. Each of the four CSB accident investigation details both human and financial tolls which these incidents had on the company and the surrounding communities.

The CSB’s “Business Case for Safety” emphasizes that based on its more than 130 incidents it is clear that hundreds of billions of dollars have been spent as a result of chemical disasters in the United States. To ensure the safety of all Americans it is critical that chemical safety lesson are learned and shared among

diverse stakeholders and across industries to prevent accidents.

Chairperson Sutherland said, “If the CSB’s many safety lessons prevented at least one catastrophic incident, the money saved by preventing damage to the facility and surrounding community, avoiding legal settlements, and saving human lives far exceeds the agency’s $11 million annual budget.”

The CSB concludes that strong safety programs are critical for the economic success of the chemical and petrochemical industries. The CSB’s continued collaboration with industry, regulators, standards setting bodies and other professional organizations proves that the CSB has a vital role in driving critical chemical safety change in the United States.

Monday, April 14, 2014

HAZOP training

April 14, 2014- For those of you who wish to know and

understand more about HAZOP (Hazard and Operability Study)

and associated stuff, there are basically three ways to do it. Here is a list of them with their associated advantages and disadvantages:

a) Surf the web- just like you likely found this page while searching for terms like HAZOP or HAZOP Study free pdf.There will be hundreds or even thousands of articles that range from the fairly easy to understand to the completely complex ones which may leave you gasping for breath (or bored enough to go to sleep). Also the variety and scope will be mind boggling. You will learn all the jargon though...to impress your friends who have no idea about HAZOP studies.

b) Read a book. There are a few about Risk Assessment and HAZOP. None of them covers everything though, so you will have to buy at least three of them to learn anything of value. Of course even if you read them and understand the concepts, you will have nothing in your hand that proves to the world that you know your stuff!

c) Download the HAZOP e-learning course from Abhisam, that covers everything about HAZOP in one, short, easy to understand course. There are several animations and simulations that explain key concepts and make this difficult to understand subject very easy to learn. Besides you can take their online exam and get a Certificate of Competency too, on passing!

a) Surf the web- just like you likely found this page while searching for terms like HAZOP or HAZOP Study free pdf.There will be hundreds or even thousands of articles that range from the fairly easy to understand to the completely complex ones which may leave you gasping for breath (or bored enough to go to sleep). Also the variety and scope will be mind boggling. You will learn all the jargon though...to impress your friends who have no idea about HAZOP studies.

b) Read a book. There are a few about Risk Assessment and HAZOP. None of them covers everything though, so you will have to buy at least three of them to learn anything of value. Of course even if you read them and understand the concepts, you will have nothing in your hand that proves to the world that you know your stuff!

c) Download the HAZOP e-learning course from Abhisam, that covers everything about HAZOP in one, short, easy to understand course. There are several animations and simulations that explain key concepts and make this difficult to understand subject very easy to learn. Besides you can take their online exam and get a Certificate of Competency too, on passing!

Sunday, February 23, 2014

Human Factors in HAZOP & other risk assessment techniques

How important are human factors when carrying out risk assessment studies such as HAZOP, LOPA and other techniques? Very much important it turns out, although until now most practitioners did not include this factor in their risk assessment studies. But of course we know that accidents can and do happen due to human error. Is there a policy guideline for this in place? Yes, it turns out that there is, in fact it was released a long time ago.

The UK Health and Safety Executive reportedly is mulling to include a "human" factor in risk assessment of major hazard facilities (COMAH). They have released a policy roadmap that details this here.

For example if the Risk assessmnet of a major hazard facility shows that it is essential to carry out some maintenance tasks regularly to reduce the risks, then a human factors analysis should be done to find out if

a) whether the task itself could be skipped?

b) whether any alarms can be raised if this is skipped due to error, negligence or simply laziness?

c) whether an incompetent performance of this task could result in an accident?

Very valid questions and a long way to go to analyze all the myriad things that humans can and many times actually do wrong!

So in your next HAZOP review one of the deviations should be "operator did not perform the task at all OR he did not perform the task correctly". This condition has not been included in any HAZOP formats or software to the best of our knowledge but should be and will, in the near future.

If you would like to know more about this aspect, you can check out the Abhisam course here.

The UK Health and Safety Executive reportedly is mulling to include a "human" factor in risk assessment of major hazard facilities (COMAH). They have released a policy roadmap that details this here.

For example if the Risk assessmnet of a major hazard facility shows that it is essential to carry out some maintenance tasks regularly to reduce the risks, then a human factors analysis should be done to find out if

a) whether the task itself could be skipped?

b) whether any alarms can be raised if this is skipped due to error, negligence or simply laziness?

c) whether an incompetent performance of this task could result in an accident?

Very valid questions and a long way to go to analyze all the myriad things that humans can and many times actually do wrong!

So in your next HAZOP review one of the deviations should be "operator did not perform the task at all OR he did not perform the task correctly". This condition has not been included in any HAZOP formats or software to the best of our knowledge but should be and will, in the near future.

If you would like to know more about this aspect, you can check out the Abhisam course here.

Sunday, September 29, 2013

Risk Assessment techniques in the Process Industry

Risk Assessment is defined as the qualitative or quantitative determination of the degree of hazard (or threat) posed by a system, process, or any other entity. While risk assessment is a generic term which may apply to almost anything like the risk of an individual dying immediately after being insured to the probability of a car meeting with an accident while going on a highway, it means different things in the process industry. In the process industry, which can mean a wide variety of industrial sectors right from oil and gas, chemical processing to mining, risk assessment is the quantification or subjective assessment of the degree of hazards that could turn into accidents such as explosions, fire, leakages & spills and so on.

As you can imagine there are several different ways and methods of risk assessment in these industries and there are both quantitative as well as qualitative methods. Quantitative methods of risk assessments are known as QRA or Quantitative Risk Analysis. The subjective ways are many and they comprise of techniques such as HAZOP, HAZID, what if analysis and LOPA (which is also known as semi quantitative). Thus HAZOP is a kind of subjective risk assessment technique used mainly in the process industry (although reportedly some variants are also used in the software and allied sectors).

Among all these techniques, the most popular one today is HAZOP.

For example, consider the gas storage tanks (spheres) above. There is obviously a risk associated with this storage which is the risk of explosion and or fire or gas leak. Now to assess this risk we can use a variety of risk assessment techniques, the main one being HAZOP. We will break down the unit into logical nodes and each node will then be analyzed using the HAZOP technique to provide an estimate of the risk associated with the storage.

As you can imagine there are several different ways and methods of risk assessment in these industries and there are both quantitative as well as qualitative methods. Quantitative methods of risk assessments are known as QRA or Quantitative Risk Analysis. The subjective ways are many and they comprise of techniques such as HAZOP, HAZID, what if analysis and LOPA (which is also known as semi quantitative). Thus HAZOP is a kind of subjective risk assessment technique used mainly in the process industry (although reportedly some variants are also used in the software and allied sectors).

Among all these techniques, the most popular one today is HAZOP.

For example, consider the gas storage tanks (spheres) above. There is obviously a risk associated with this storage which is the risk of explosion and or fire or gas leak. Now to assess this risk we can use a variety of risk assessment techniques, the main one being HAZOP. We will break down the unit into logical nodes and each node will then be analyzed using the HAZOP technique to provide an estimate of the risk associated with the storage.

Tuesday, September 24, 2013

PHA-Process Hazard Analysis

Today, we will examine in brief what is referred to in industry parlance as PHA or Process Hazard Analysis. PHA refers to any technique that is used to identify hazards that may exist in any industrial, manufacturing or any such similar activity. More specifically it refers to the hazards that are to be identified in the process industry. As you know the "process industry" is a generic term that covers a wide range of industries such as chemicals, oil and gas, power generation, mining and the like. These industries have several hazards present due to the nature of their operations and they need to be identified, reduced to a safe enough level to minimize the risk of accidents and thus mitigate them.

PHA thus refers to any technique that can reliably do so. There are several PHA techniques that are used in the process industry and they are HAZOP (Hazard and Operability Study), What-if analysis, HAZID, LOPA (Layer of Protection analysis) to name a few. Out of these HAZOP and LOPA are growing in popularity worldwide.LOPA as a PHA technique is also used as a SIL determination technique. SIL is an acronym for Safety Integrity Level and we will cover that in a separate post.

Thursday, September 19, 2013

HAZOP-Hazard and Operability Study

Sep 19, 2013- HAZOP is an acronym for the popular Hazard and Operability Study. However the focus of most HAZOP studies seems to be more on the "Hazard" part rather than the "Operability" part. Did you notice it? The operability refers to how easy or how difficult would it be to operate the plant in its current form. For example, it is easy to say (and record) that in case of an upset the plant operator will close the Hand Valve HV101. However where is it located? Is it easy to close it? Is it accessible? What if it requires an effort just to reach it? Would the handle get jammed? These operability questions are very relevant in HAZOP studies and must be addressed.

In recent years, almost nothing is discussed in HAZOP studies about the plant's operability. On hopes that in the coming years the operability factors will also play an important role. After all, a plant that is easy to operate and run should cause less stress amongst operating staff and thereby cause lesser dangerous incidents or accidents, is it not?

One good move in recent years has been though that "human factors" are seen to be as important as the plant design factors and these would be given weightage in the new HAZOP studies.

For an in-depth course on the Hazard and Operability technique, you can refer to the Abhisam training course on HAZOP.

Subscribe to:

Posts (Atom)